It used to be that production and storage halls were built using masonry technology, where the external wall was both the structure and the partition separating it from external conditions. With the development of design methods, other types of structures began to be used, e.g. skeletal structures in which the loads are transferred through the skeleton to the foundations, and the external partitions should be made as lightweight curtain walls that do not transfer the main loads, but only the loads from dead weight and wind or snow. What remains to be decided is what the curtain walling should be made of.

We distinguish between several types of lightweight cladding systems:

- Sandwich panels – these are panels made of thin sheet metal with a core filling of polyurethane foam, PIR, mineral wool or polystyrene. Thicknesses range from tens to hundreds of millimetres.

- Sheet – wool – sheet arrangement, where we have two trapezoidal sheets, usually with a different profile (strong on the outside and weaker, more aesthetically pleasing on the inside) filled inside with mineral wool assembled on site.

- Cassette – wool – sheet, where the walls are built with cassettes that are also the substructure, the cassettes are filled with mineral wool and trapezoidal sheet is fixed on the outside.

- Trapezoidal metal with or without insulation. Without insulation – trapezoidal sheet metal alone. With insulation – e.g. mineral wool over vellum or, in the case of roofs, hard mineral wool and a roofing membrane attached to it.

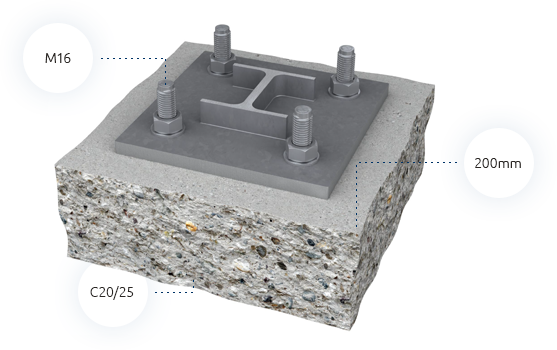

There was still the question of how to connect the cladding to the supporting structure of the building. This led to the development of a range of screw fasteners, both self-drilling for steel substrate and self-tapping for concrete substrate.

We begin the fastening calculation by determining the support system for the enclosure, i.e. the secondary structure, this will determine how the elements of the enclosure are supported and what they are fastened to. We calculate the fastenings mainly in terms of wind suction.

Which requires determining the forces acting on the wall or roof and transferring them to the support structure. EasyFix makes it easy, based on the building geometry, to calculate the loads and transfer them to the supports. There are five calculation modules to choose from, depending on the type of element roof, wall and sheet metal, composite panel.

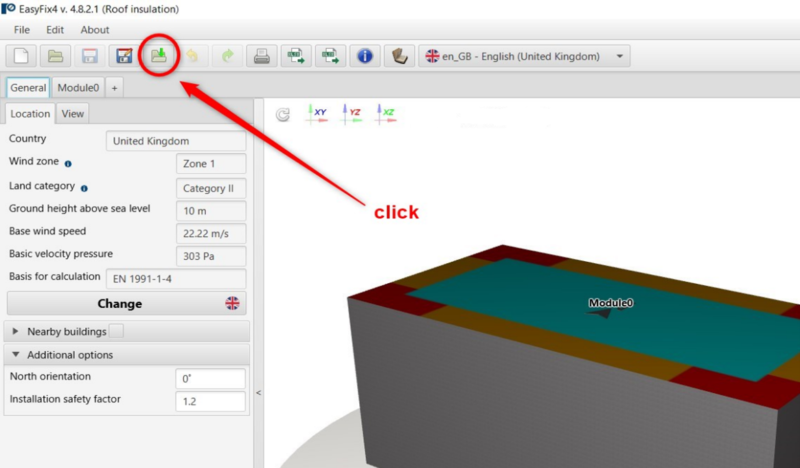

An advantage of using EasyFix software to design enclosures is the “Import” function, which allows the shape of the object and the materials used (sheet metal parameters) to be transferred between modules.

Clicking on the import button allows saved calculations made by another module to be loaded for lightweight housing calculations.

Do you need design support ? We will help! – Rawlplug Technical Helpdesk

Download and check the program EasyFix

Find out more at rawlplug.com

Comment section

Share this article: